International Space Elevator Consortium

August 2025 Newsletter

In this Issue:

Save the Date: ISEC 2025

Chief Architect’s Corner

Dennis Wright Visits GEIC

Tether Materials

History Corner

Writer’s Circle

Upcoming Events

Contact Us

Save the Date: ISEC 2025

ISEC 2025 is just around the corner! Our virtual conference will be held September 6th and 7th, so save the dates. Abstracts are in and we have speakers from around the world discussing space elevator topics from tether material construction to large-scale architecture issues. There will also be open discussion sessions where new ideas can be brought up.

Keep your eye on www.isec.org/events for the schedule and connection link.

Chief Architect’s Corner

by Pete Swan

Modern-Day Space Elevator’s Evolutionary Growth Towards Apex Anchor Revolution

The space elevator community again published an article within the British Interplanetary Society’s Journal of the BIS, in November 2024. The title, which is the same title as this article, reflects the future evolution of Modern-Day Space Elevators as an infrastructure and commercial environment for delivering cargo to space routinely, cleanly, inexpensively and is environmentally friendly. It was led by Cathy W. Swan and co-authored by me. You can find it at this link: https://www.isec.org/recent-publications.

In the article, we address the research covered in our latest Apex Anchor report and discuss how cargo is moved into space from its Earth Port to GEO altitude and then on to an Apex Anchor. Apex Anchors sit at the top of the full-service transportation infrastructure, and they represent a “Green Road to Space.” At full capability, Apex Anchors will be revolutionary as they capture satellites, release them, refuel, repair, assemble and then, in the future, they will facilitate human transportation for transit or long-term residencies.

Recent research into the remarkable capabilities and characteristics of Modern-Day Space Elevators has shown there are evolutionary and revolutionary aspects that will surprise and encourage future customers and investors.

+ Space elevators’ mission spacecraft are released at high velocities and can reach other planets and moons with rapid transit through daily releases. Satellites can be virtually any size when assembled at Apex Anchors.

+ Research has recently shown a 70% delivery efficiency of mass at liftoff to GEO, Apex Anchor and beyond [vs. 2% by rockets to GEO] with huge movement of remarkable masses to GEO and beyond. This is achieved every day while protecting our atmosphere as the “Green Road to Space” – no burning of fuels in our atmosphere or leaving debris along the way.

This Journal of the BIS article identified these transformational capabilities and helped to place them in the evolutionary development of Modern-Day Space Elevators. It then illustrated the revolutionary characteristics that will greatly enhance customers’ capabilities. Apex Anchors will be revolutionary – enabling so many missions; but in fact, they will start as “truck stops” capable of off-loading payloads, capturing incoming payloads, refueling, repair and, of course, ensuring stability of space elevators. This concept of full service along each 100,000 km tether is remarkable and will help lead the revolution in capability and capacity.

My request to all readers of this ISEC Newsletter is to consider attending meetings and conferences, assisting with the dissemination of the technical information, and, if you have any ideas to share, contributing to the development of professional reports to increase our knowledge base. We have had many articles published over the last three years, but we would welcome new contributors and concepts to be shared with others. Please think about this and work with us to reach publishers, refine ideas, and develop outreach.

Dennis Wright, President of ISEC, Visits the GEIC

by Adrian Nixon & Peter Robinson

Many of you will know that graphene was first isolated in 2004 at the University of Manchester in the UK. Since then, the university has become a centre for graphene research and commercial development.

The Manchester campus has two world-class centres; the National Graphene Institute (NGI) focusses on fundamental research and the Graphene Engineering Innovation Centre (GEIC, pronounced like “geek”) is configured to support spin-out and spin-in companies to develop and commercialise new technologies based on graphene and two dimensional (2D) materials.

Graphene Engineering Innovation Centre (GEIC), Manchester, UK. Image credit: Adrian Nixon.

Adrian Nixon and Rob Whieldon are partners at the GEIC with their Nixene Publishing company. They write a monthly journal that reports on the latest academic and commercial graphene and 2D materials developments around the world.

So, when Dennis Wright mentioned that he would be travelling to the UK and would like to visit the GEIC, we set about organising a visit and mini conference to discuss the space elevator and the development of strong materials such as graphene. We must say a big thank you to James Baker, the CEO at Graphene@Manchester (the organisation that includes the GEIC).

James welcomed us all and introduced us to the graphene ecosystem at Manchester. He presented an overview of the GEIC. Since it officially opened in 2019, the GEIC has delivered over 500 projects to more than 300 companies working on proof of concept to prototype developments such as Technical Readiness Levels and Manufacturing Readiness Levels 3 to 6 (TRL/MRL 3-6). The GEIC works mainly with graphene powders in composites and inks. It also has a Chemical Vapour Deposition (CVD) lab where large scale sheets of graphene can be made on metal foils and transferred to other substrates.

James Baker presenting about the GEIC. Image credits: Peter Robinson.

Dennis started the day by providing an overview of the space elevator concept and the economic case for building one. He also introduced the International Space Elevator Consortium. He summarised the purpose of ISEC as follows: To expand and preserve the knowledge base, promote the construction of space elevators, and to educate people about the technology and its transformative capabilities.

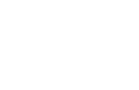

Dennis Wright presenting about the space elevator. Image credits: Peter Robinson.

Dennis also presented his recent work simulating the space elevator using computer modelling to explore the way the space elevator tether responds in mechanical, electrical, magnetic, and radiation environments.

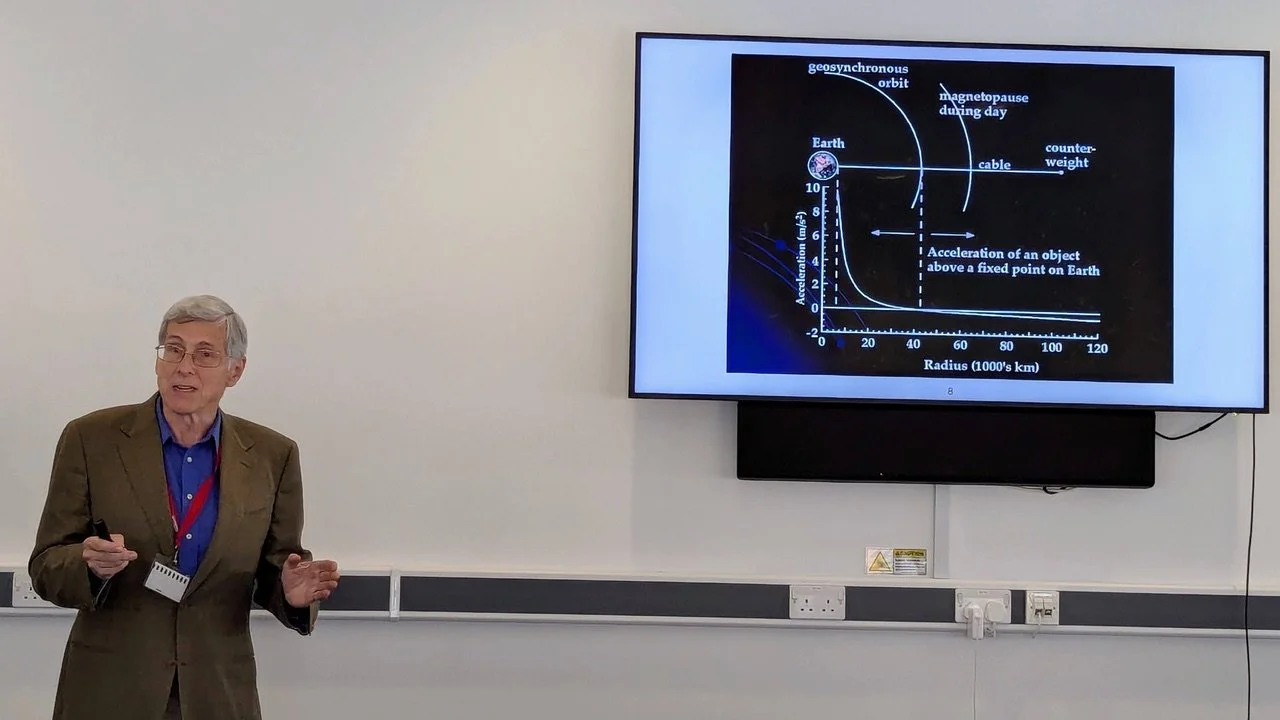

Then Rob Whieldon presented about graphene applications in space and gave an overview of how our journal tracks and analyses all this activity.

Rob Whieldon presenting about graphene applications in space and the Nixene Journal. Image credit: Peter Robinson.

Adrian Nixon then gave a presentation about strong materials for the space elevator. This included the latest developments making graphene by continuous manufacturing processes around the world.

Adrian Nixon presenting about strong materials for a space elevator. Image credit: Peter Robinson.

We had a break for a working lunch where James Greer of SmartIR presented a working prototype of a graphene emissivity control device. Using graphene and applying a voltage, the SmartIR team can make walls of satellites either reflective or transparent to infrared radiation. This enables satellites in space to regulate their heat more effectively, keeping them cool when in the sunlight and warm when in the darkness of space. SmartIR has launched two satellites in low Earth orbit on SpaceX Falcon 9 transporters and the technology is being successfully tested in space.

Adrian Nixon with James Greer of SmartIR demonstrating the graphene thermal control system for satellites. Image credit: Peter Robinson.

James Baker then gave us a tour of the GEIC facility. We began in the high bay which is a flexible space that can be configured for industrial scale up of a wide range of projects.

L-R: Rob Whieldon, James Baker, John Knapman, Dennis Wright, Peter Robinson, James Greer, Gurbir Singh, Sera Sipahioğlu, Nikki Mansouriboroujeni. Image credit: Adrian Nixon.

We moved on through a range of laboratories, where James showed us how graphene powders are incorporated with other materials to make graphene enhanced products using industrial scale equipment.

L-R: Sera Sipahioğlu, Rob Whieldon, Dennis Wright, John Knapman, James Baker. Image credit: Adrian Nixon

Then James took us into the Chemical Vapour Deposition (CVD) laboratory. Very few people get to go in here. This lab has several CVD machines. The one you can see in the picture is the Aixtron BM Neutron. This production machine makes monolayer (one atom thin) graphene on copper foil 150mm wide by a continuous roll-to-roll process. We believe there is only one other of these particular machines in the world.

This is just a small taste of our visit. There were many areas where photography was not permitted so we cannot share with you some of the things we saw. And then there were areas that were beyond our ability to visit.

No entry sign on one of the labs at the GEIC. Image credit: Peter Robinson.

L-R: Adrian Nixon, James Greer, Gurbir Singh, Rob Whieldon, Dennis Wright, James Baker, John Knapman, Alex Sarov, Poppy Guy, Peter Robinson, Sera Sipahioğlu. Image credit: Peter Robinson.

We ended the day at the reception, with a photo opportunity at the home of graphene with the Manchester skyline in the background.

We were all exhausted after a full day concentrating on absorbing the scale of the innovations that are being enabled at the GEIC. Graphene is made and tested here in powder form as well as CVD graphene on a large scale.

These graphene materials are far from space elevator quality at present. However, take note that the work being done here in 2025 would have been considered impossible just twenty years ago.

An observation by James Baker seems an appropriate way to conclude this article:

"I have often been very cautious about talking about Space Elevators (as it’s quite abstract and very challenging concept for any engineer or scientists to comprehend) but this week brought back some prior memories and thoughts about how we are now writing our “Future Histories”. Almost exactly 12 years ago whilst I was working for a large corporate organisation BAE Systems and was invited to a graphene conference to give a keynote about opportunities in defence and aerospace. I honestly was very sceptical and think my punchline was “maybe I would come back in 20+ years” and see if the technology had matured enough to be of interest.

"It was therefore with some irony that 6 months later I started a new role and opportunity at Graphene - The University of Manchester and now less than 12 years later we are seeing Graphene playing a commercial role in many sectors from construction to aerospace to energy to water treatment to healthcare.

"My reflection therefore is that often the future is maybe closer than we think.”

Tether Materials

by Adrian Nixon

Continuous Manufacturing of CVD Graphene Around the World

In the early years of the 21st century, graphene was considered impossible to exist as a single atomic layer of carbon. Then, two scientists in Manchester, Andre Geim and Konstantin Novoselov, isolated the single atomic layer of carbon and proved the impossible to be possible. They won the Nobel Prize in 2010 for this discovery and this field of 2D materials.

The next challenge was how to make this superlative material in industrial quantities. Development over the years focussed on making graphene powders and gradually the price has come down from tens of thousands of dollars to hundreds of dollars per kg. Some grades of graphene powders are now being talked about in terms of tens of dollars per kg. As the economies of scale kick in, the costs will come down further.

Graphene powder is not the form of the material that will ultimately make a space elevator tether. For this we need large scale continuous sheets of graphene that are layered on top of one another to create an entirely new product that will be the strongest, most stable material ever produced.

The process that makes large scale sheets of graphene is called chemical vapour deposition (CVD) and makes large scale sheets of monolayer graphene on metal foil. The process is described in a previous article [1].

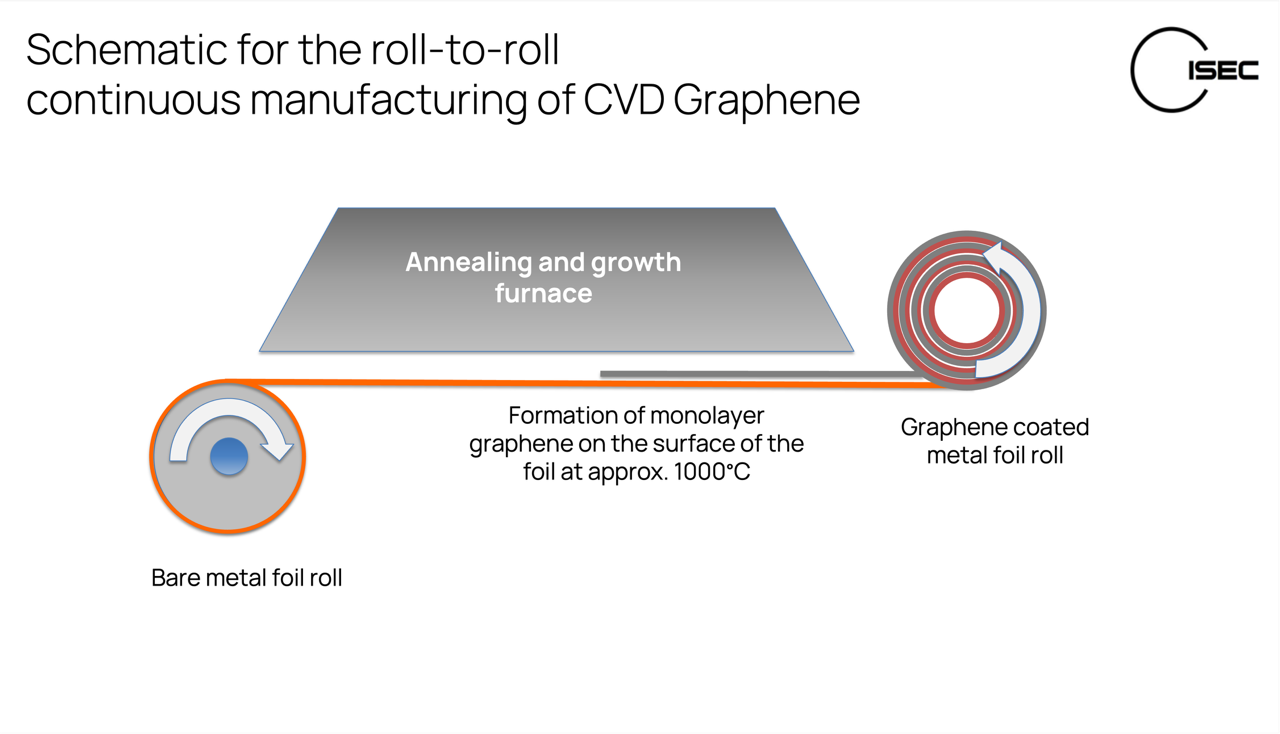

The CVD method began as a batch process. Then researchers developed continuous methods for making graphene on copper foils. These processes are all roll-to-roll where a roll of foil is unreeled as passed through a furnace which anneals and reduces the metal to minimise grain boundaries and remove metal oxides from the surface. This is followed by a growth zone where the graphene monolayer is formed on the surface. The last stage is where the foil is cooled and wound back into a roll. Figure 1 represents a simplified view of the process.

Fig 1. A schematic of the roll-to-roll process for making CVD graphene.

This continuous CVD graphene manufacturing process has been developed around the world, and it is time to look at the progress of this activity. There appears to be two forms of this process: a horizontal furnace and a vertical design. Both create similar end products.

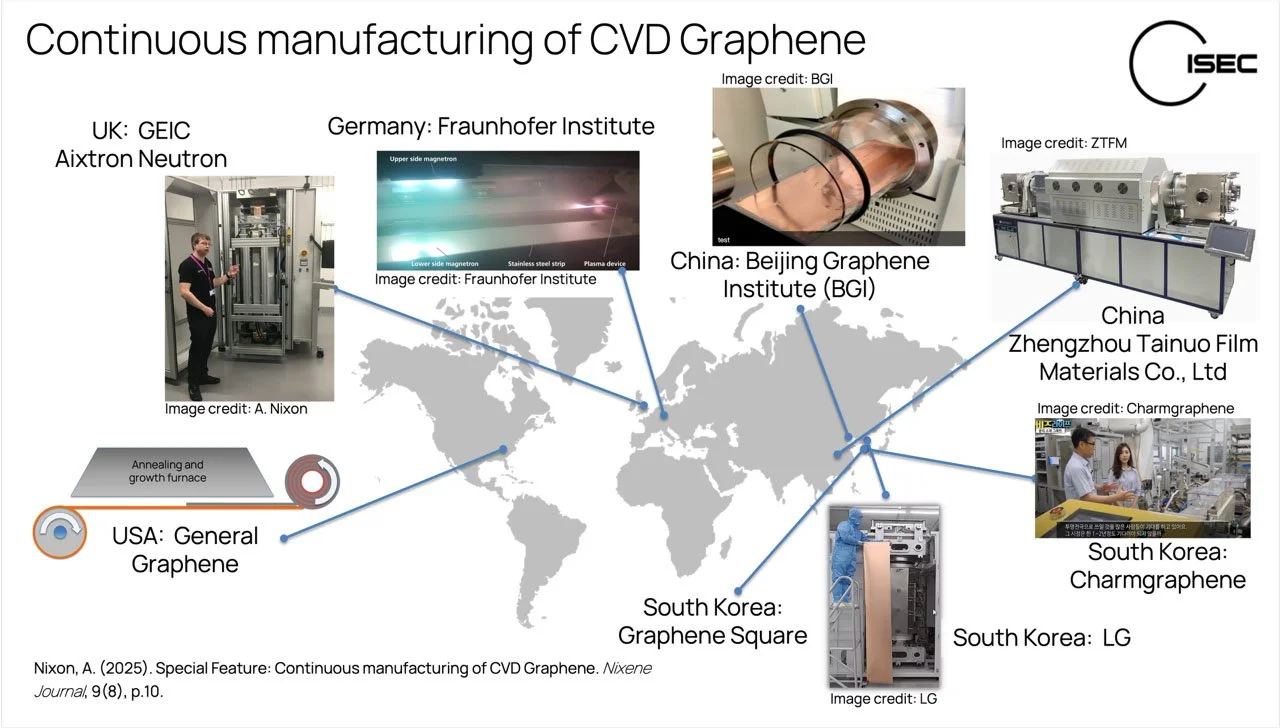

Fig 2. Continuous manufacturing of graphene worldwide.

Figure 2 shows the seven locations that have been publicly disclosed. These companies are making polycrystalline graphene rather than single crystal. To find out more about what crystallinity means in this context please refer to our previous article [2].

In the USA, the company General Graphene has developed a horizontal furnace, and their latest production line is called Gen 3.0. The process uses 400mm wide foils and makes graphene at a speed of 0.4m/minute. The company claims they can make 10,000 m2/year of graphene on copper foil. They have also developed wet and dry transfer processes for separating the graphene from the metal.

In the UK, the Graphene Engineering Innovation Centre (GEIC) has an operational Aixtron BM Neutron vertical CVD production machine. This makes graphene on reels of copper foil that are 150mm wide and up to 50m long.

The Fraunhofer Institute in Germany has developed a new horizontal roll-to-roll process that can make graphene on copper foils at speeds of up to 1m/minute.

In China, the Beijing Graphene Institute (BGI) has a facility that can make CVD graphene continuously; however little is publicly disclosed about this capability. Also, in China the Zhengzhou Tainuo Film Materials Co., Ltd has developed a horizontal plasma enhanced (PECVD) production machine that can make CVD graphene continuously. This is a continuous-batch process because the low pressures involved means the machine must be depressurised to extract the graphene coated foils after each production run.

South Korea has the most advanced CVD manufacturing capability. LG has a vertical furnace that can make graphene on foils 400mm wide and 1 kilometre long at speeds of 1m/minute. CHARMGRAPHENE has developed a horizontal process that can make graphene at speeds of up to 2 metres per minute and lengths of 1 kilometre. Both these processes are limited to 1 km because that is the maximum length of foil they can manage on a reel.

These processes are all focussed on making CVD graphene for electronics applications rather than space elevator tether. However, this work is foundational to tether manufacture because they are pushing the boundaries of quality, speed, and length of graphene that can be made by a continuous process. CVD graphene is becoming an industrially manufactured product, and we will continue to monitor developments around the world.

References:

1. Nixon, A. (2021). 2021 August International Space Elevator Consortium Newsletter. [online] International Space Elevator Consortium. Available at: https://www.isec.org/space-elevator-newsletter-2021-august/#tether.

2. Nixon, A. (2024). Space Elevator Tether Materials: The Crux of the Matter. [online] International Space Elevator Consortium. Available at: https://www.isec.org/space-elevator-tether-materials [Accessed 27 Jul. 2025]. Forms of Graphene.

History Corner

by David Raitt, ISEC Chief Historian

Space Elevators in the Forgotten Internet

There was a great article on the BBC website the other day about the forgotten internet; how slowly but surely, much of the internet is vanishing because of AI, Google’s new approach to searching, old computers, no longer extant browsers, websites not being updated, and so on. But, as the article explains, artefacts of the early web are still out there if you can find them! (https://www.bbc.com/future/article/20250731-a-journey-into-the-heart-of-the-forgotten-internet).

So, I decided to try and look through some of the old websites given as examples and see what I could find relating to space elevators. The Internet Archive, which began in 1996, is dedicated to preserving the web, particularly through its Wayback Machine, which lets you put in any URL to find snapshots of that site at pretty much any given date. Besides hundreds of billions of web pages, the archive includes millions of books and texts (including ISEC study reports uploaded by me), millions of audio recordings, concerts, videos, images, and software programs. Simply entering the words space elevator throws up 431 audio media, 409 texts, 218 movies, 152 etree, 117 pieces of software, 58 data, 33 images, and 5 collections. Ostensibly dating from 1909 to 2025, not all will be totally relevant; for instance the 1909 item is a cereal map of Alberta, which among other things shows the number of (grain) elevators at railway stations!

Putting the words in quotes “space elevator” reduces the number of items to 75 texts, 64 audio clips, 51 movies, 12 bit of data, 8 etree, 3 images, and 1 software from 1977-2024 - again not all relevant. But some interesting new stuff is thrown up, for instance, one of the two 1977 items is a NASA Technical Memorandum (NASA TM-75174) entitled “A space necklace about the Earth” by G. Polyakov and published on 1 December 1977. The description reads:

“A space elevator is forecasted for the first quarter of the 21st century, that will consist of a cable attached at the earth's equator, suspended in space by an artificial satellite in geosynchronous orbit. It is stated that such a transport system will supplement rockets as the railway supplements aircraft. Specific aspects of the system are examined, including provisions for artificial gravity, the development special composite construction materials exhibiting high strength and low mass, and spacecraft launching from the elevator.”

(https://archive.org/details/NASA_NTRS_Archive_19780010146) Interestingly this document does not seem to be referenced in David Smitherman’s 1999 NASA Space Elevators conference proceedings.

The second item from 1977 is by Hans Moravec entitled “Orbital Skyhooks” and is a two-part computer simulation depicting a dynamic orbital skyhook, a cable in a sub synchronous orbit that rotates to touch the planet surface. The first part shows a touch-down and take-off of an end of the cable at a hypothetical space port in Africa. The second segment shows an animated diagram of the cable skyhook as it rotates and orbits to "walk" the planet’s surface (https://archive.org/details/sailfilm_skyhook).

Using the Wayback Machine, by entering a website you can get an overview of when that site was crawled and get the information found on the website at that time. In 2000 I initiated a study on Innovative Technologies from Science Fiction for Space Applications (ITSF). We set up a website to provide information about the study and how people could help by providing details of technologies found in science fiction texts and images and then evaluating whether these might actually be applicable for space exploration. The space elevator was one of these technologies. The website served its purpose, but has long disappeared - however, it can still be found on the Wayback Machine (https://web.archive.org/web/20010419065841/http://itsf.spaceart.net/).

Another site mentioned in the BBC article was Wiby with a library consisting of “handmade, idiosyncratic sites of the early web,” (https://wiby.me). I searched for “space elevator” again and came across a whole host of items pertaining to the concept (though not all on “our” concept!) and several of which I do not remember coming across before. One for example was, “Free Launch Escape Radial Tower - Taken by the Sky - Orbital Siphon Development”, a simulation in 1997 (http://endgame.co.uk/idletheory/siphon/analytics/). This relates to a paper by Colin McInnes and Chris Davis presented at the IAC in Fukuoka in 2005 entitled “Novel Payload Dynamics on Space Elevator Systems” (http://endgame.co.uk/idletheory/siphon/analytics/paper2005/IAC-05-D4[1].2.07.pdf).

Another item listed on Wiby is entitled “Space Warfare” and notes that innovative ideas such as the space elevator will require major funding. Another article by Bill Dietrich is entitled “Reasoning about the Manned Space Program” which tries to present facts and logic and solutions rather than just opinions. The article is some ten years old, and the space elevator is mentioned nine times (https://www.billdietrich.me/ReasonMannedSpaceProgram.html). Yet another site discusses Megascale Engineering (https://www.aleph.se/Trans/Tech/Megascale/), and focuses particularly on beanstalks or orbital elevators. There are also many links to articles such as “The Orbital Tower” by Frank Rosen dating from April 1995 (https://www.aleph.se/Trans/Tech/Megascale/).

And if you’re looking for space elevator gifs over time, then try out GifCities (https://gifcities.org/)!

Writer’s Circle

Note from Dr. Swan: Joyce has been an enthusiastic supporter of ISEC (editor of our research report: The Apex Anchor: Full-Service Transportation Node at the top of the Gravity Well). She was a guest speaker at our 2024 Space Elevator Conference and has written this science fiction novel.

Battle of Jericho 2038

by J. F. Elferdink

Space elevators—the backdrop of Battle of Jericho 2038—will allow us to build cities on the Moon and to collect solar power energy from space, but as with most cutting-edge technology, in the wrong hands they can also do harm to the masses. Integral to the story is: Researchers with Callie's Collective soon recognize the elevator program's potential for far more than storing grain in low Earth orbits or sending a few astronauts into space; they prove outer space can provide solutions to Earth's most severe problems such as inexpensive electricity. The Collective becomes the primary operators of a program called the Galactic Harbour, using Space Elevators, sometimes coupled with rockets, to become the gateway to the stars that a rare few physicists and science fiction authors had even dreamed possible. Purchase at: https://www.smashwords.com/books/view/1814368 and/or https://www.amazon.com/Battle-Jericho-2038-J-Elferdink/dp/B0FJZRRGZR

Upcoming Events:

Virtual Space Elevator Conference 2025

Sponsored by the International Space Elevator Consortium

https://www.isec.org/events/isec2025

Saturday, September 6th, through Sunday September 7th, 2025

76th International Astronautical Congress

Sponsored by the International Astronautical Federation (IAF)

https://www.iac2025.org/about/

Monday, September 29th, through Friday, October 3rd, 2025

International Convention Centre, Sydney, Australia

International Space Development Conference 2026

Sponsored by the National Space Society

https://www.isec.org/events/isdc2026

Thursday, June 4th, through Sunday, June 7th, 2026

Space Elevator Session, Saturday, June 6th

Hilton McLean Tysons Corner

77th International Astronautical Congress

Sponsored by the International Astronautical Federation (IAF)

https://iac2026antalya.com/

Theme: “The World Needs More Space”

Proposed Dates: October 5th through October 9th, 2026

Antalya, Turkey

Contact Us:

Our website is www.isec.org.

You can find us on Facebook, X, Flickr, LinkedIn, Instagram, YouTube, Mastodon, Threads, Bluesky and Reddit.

Support us:

Sign up to be a member at: https://www.isec.org/membership

You can also give directly using the “Donate” link at the bottom of our website page.

Does your place of employment do matching funds for donations or volunteer time through Benevity? If so, you can make ISEC your recipient. Our 501(c)(3) number is 80-0302896.