International Space Elevator Consortium

August 2021 Newsletter

In this Issue:

Editor’s Note

President’s Corner

July Webinar Results

Upcoming Webinar

Volunteer Opportunities

Tether Materials

History Corner

Upcoming Events

Contact Us/Support Us

Editor’s Note

Dear Fellow Space Elevator Enthusiast,

It’s my birth month again, and the quarantines and travel lockdowns have ruined yet another Space Elevator Conference for me! They typically were held the weekend of my birthday, or just after, so it was one of my presents to myself to attend, learn, and mingle with a fantastic group of men and women who are dedicating their professions and/or volunteer time to building a “Green Road to Space.”

As we did last year, we will be holding an online meeting/webinar. The cost of admission is merely the cost of membership! All ISEC members will receive a link via email with instructions on how to attend the meeting. It won’t be exactly ON my birthday this year, but very close, so this will be one of my presents to myself--to socialize, albeit online only, with the scientists and engineers that are dedicated to getting this project off the ground, if you will excuse the expression. Won’t you join us?

Sandee Schaeffer

Newsletter Editor

President's Corner

by Pete Swan

Wide-eyed Believers

This month’s Ad Astra magazine (NSS quarterly) contained a great article by Anthony Paustian entitled “The Red Pill of Possibility.” He discussed the choice of dreaming big and charging ahead with new technologies vs staying with less risky current technologies. His examples were (of course) from the space arena. He aggressively explained that many who risked would fail along the way; but, some would succeed in the long run. As I read the article, I could see remarkable parallels with our own situation. We are charging ahead in an arena where very few people are even aware of how much progress we have achieved in the technologies and their many challenges. We are at the beginning of developmental phases and our existence has shaken most people’s concepts of where Space Elevators are. His last sentence was well said:

“….The road to space settlement will be paved through a large, growing group of wide-eyed believers, and that’s exactly what NSS stands for.” [pg 17 Ad Astra 2021-2]

I believe he was also talking about ISEC. We are in a very good position now, with huge potential in the very near future. We have a remarkable story and must be aggressive in sharing our current successes and explain our future path. I believe our vision, strategy and approach will “win over” many of the people waiting on the sidelines for progress. Here are my three items that will ensure our “wide-eyed” believers are successful in the long run:

Vision:

Space Elevators are the Green Road to Space while enabling humanity's most important missions by moving massive tonnage to GEO and beyond. They accomplish this safely, routinely, inexpensively, and daily - all while being environmentally neutral.

Strategy: Dual Space Access Architecture combines the strengths of both advanced rockets and Space Elevators. This idea enables numerous space activities that will better life on Earth for all people - making Earth greener, cooler and allowing continued growth and prosperity. In addition, it will show how Space Elevators will enable movement off-planet with a greener and more efficient approach. As such, we see: Rockets to Open up the Moon and Mars with Space Elevators to supply and grow the colonies.

Approach: Raise the awareness that Space Elevators will enable the dreams (visions) of many by moving massive payloads to GEO and beyond. We should be continuously asking the questions of how much mass do you need for your vision and then explain how we can fulfill those needs.

24 July 2021 Webinar Success

Our Board of Directors member, Karyn Gleeson, produced a webinar entitled: “A Dual Space Access Architecture--Rockets and Space Elevators.” The aim was to familiarize participants with the remarkable strategy where Space Elevators do the heavy lifting while working with advanced rockets in the future to fulfill the dreams of many. If you were to view the visions of Dr. Glaser, Dr. O’Neill, Jeff Bezos, Elon Musk, the Moon Village Association and so many more (including NASA’s Artemis Program), you would be amazed at how similar our hopes and dreams are. We are moving off-planet. We are trying to help understand (and repair) Earth’s environment. We have big visions and high hopes for the future.

The Webinar showed these visions and explained where the Space Elevator is in this developmental cycle. It then shared the inherent strengths of Space Elevators and future Advanced Rockets that will be available to help fulfill these visions. One question we must ask ourselves when we have aggressive visions in space is: What are the requirements for mass and into which orbital locations? The webinar explained the poor delivery statistics of rockets while showing their excellent capabilities to go to any orbit and move people rapidly through radiation belts. In addition, Space Elevators – as a permanent space infrastructure – have tremendous capabilities to move massive cargo to GEO and beyond while doing it as the Green Road to Space. Please go to our website’s recorded webinar to view the presentation and discussions. https://www.isec.org/recorded-webinars

Member-Only Meeting

Mark your calendars for August 14th. ISEC is having its second annual online meeting. This will be a two-hour meeting with seven speakers on such topics as:

An Economic Impact Analysis of Space Elevators

Interplanetary Launches using a Space Elevator

Tether Stresses and the Atmosphere Problem

The Global Space Train

Update on the Tether-Climber Interface Study

Dual Space Architecture

This agenda will be followed by an "open mic" session for unstructured discussion. This meeting is your chance to see what ISEC is up to and contribute to the space elevator discussion.

For more details go to https://www.isec.org/events

You don't need to register for this meeting, but you do need to be an ISEC member. Membership is $50/year or $25/year for students. Please go to

https://www.isec.org/membership to sign up.

Volunteer Opportunities

Each August we re-invigorate ISEC with an “in-person” conference in Seattle while we meet and greet our friends and welcome in new players. As we have lost two conference years, we have missed the opportunities to share and discuss so many aspects of ISEC. This year, we will be having a second “members-only” webinar as a weak substitute for a three-day conference - so sad. The board of directors is trying to bring back the conference, the only question is when. Each year we had time to discuss the call for volunteers and we usually had a flurry of membership renewals and first timers. But, you now have an opportunity to contribute to the future of space development by giving time towards the following efforts being conducted (or shortly to start) within the ISEC. We have been sponsoring multiple studies each year: one finishing, one on full speed ahead, and one just starting in August. In addition, we have had “working groups” conducting independent activities for the last decade. The following is a short description of the activities that need volunteers; study contributing authors, reviewers and members of active committees listed below. Please contact me [pete.swan@isec.org] if you are interested in any of the topics.

Studies:

Climber-Tether Interface Study – Lead Dennis Wright – active ½ done

New study to be announced in August –

Committees:

History Committee – Lead Matthew Farrell – monthly meetings

Research Committee – Lead John Knapman – periodic, topic driven

Green Road to Space Committee – Lead David Dotson – just beginning

During the next several months, the leads for these studies and committees will place a terms of reference and status in the newsletter explaining where they are and what is needed. Hopefully, there will be something there to entice each of you.

Tether Materials

by Adrian Nixon

Latest developments in manufacturing graphene

Dear Reader, here is a quick recap on graphene manufacturing. Then I’ll show you what is happening with the speed of 2D materials manufacturing.

Graphene is currently manufactured in two forms: as powders, and as sheet graphene.

Figure 1. Graphene powder and sheet graphene

Graphene powders are being routinely made at scales of tens and hundreds of tonnes. Industry is now learning how to use the powder form as a performance enhancing additive. It is transforming applications from plastics to concrete to metals.

For the space elevator tether, we need to focus on a more sophisticated form of graphene - Sheet graphene. You can see a one atom thin layer of sheet graphene on the surface of the copper foil in Figure 1 above. If you look carefully at the left-hand side, you will see a darker vertical strip. This is the bare metal. The slightly silvery appearance of the metal, covering most of the surface to the right, is the graphene. You are actually looking at a one atom thin layer of graphene--quite astonishing!

The main method for making large scale sheet graphene is the chemical vapour deposition (CVD) method. The starting point is carbon containing gas such as methane. This is heated to around 1000°C degrees centigrade and blown gently over a metal surface, usually copper or nickel.

The metal acts as a catalyst removing hydrogen from the carbon. The carbon lands on the metal surface and self-assembles, atom-by-atom, to form a layer of graphene. Figure 2 shows how this works.

Figure 2. The Chemical Vapour Deposition (CVD) process for making graphene

Once the surface is covered, the metal can be separated leaving the graphene to be transferred to other substrates. A small number of companies, at least one in the USA, are working on scaling up this process to make saleable graphene mainly for electronic device markets at the moment. This process currently makes sheets of polycrystalline graphene (containing defects).

Chinese, Korean and USA researchers have made near-perfect sheets of graphene on metal at square centimetre scale, and these are called single crystal graphene [1].

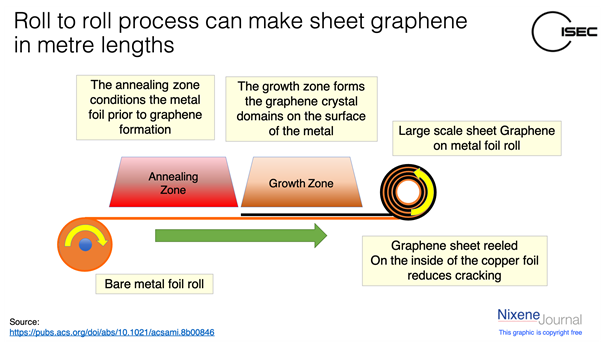

Companies in the USA and Korea have been working on graphene manufacturing by a continuous process. The current continuous graphene manufacturing process is called roll to roll (R2R) [2]. This is harder to operate and more costly to set up, but once the conditions have been optimised, it can make very large quantities of sheet graphene. Figure 3 shows the basic principles for the R2R process.

Figure 3. Roll to roll process for making graphene

The continuous process also lends itself to statistical process control techniques that makes a very consistent quality product.

The speed of manufacturing is an important parameter to pay attention to because the space elevator tether is a mega project. The tether has to be made 100,000 km (100 million metres) long and will require 12,000 individual layers.

Early developments of the CVD process in 2014 made graphene at speeds of 0.2m per hour [3].

Last year we discovered that LG electronics has increased the speed of graphene manufacturing to 1m per minute [4].

Now a new manufacturer, Charmgraphene in South Korea has announced they have doubled the speed to 2m per minute [5].

So, we have a ten times rate of increase in speed of the continuous manufacturing process for making graphene over the past seven years, with a doubling in just the last year.

Impressive as these developments are, remember we are working on a mega project. We must keep asking, ‘So What ?’ every time we encounter impressive statistics.

Even at the fastest speed achievable today, it will take over a hundred years of non-stop production to make one layer of tether. We will need manufacturers to develop production capabilities at least 30 times faster than the best available today to reach speeds of one metre per second. Each layer of tether will be manufactured in just three years. If we have massively parallel production facilities, we can make the material for a tether in this time.

If this sounds like a big ask, then remember that the industry is already making fragile materials at incredibly fast speeds. The fastest paper machine in the world is at the Zhanjiang Chenming mill in China. During a 24-hour run, the 11.15-metre-wide Valmet PM 1 produced high quality printing paper at a basis weight of 70 g/m2 and a speed of 1080 metres per minute [6]. That is 30 metres per second (98.4 feet per second).

The engineering exists to make fragile materials at high speeds. If graphene can be made at the speed of a paper machine, then the material for the tether could be made in less than two months.

In one respect, graphene is a simpler process than paper, because it requires fewer raw materials. Graphene also shares a manufacturing step with papermaking. The material is made on one forming surface, then it is separated from that surface and handled at high speeds to be processed as the end product.

The reason for telling you this is that continuous graphene manufacturing for a mega project may seem extremely high tech, but there is a wealth of transferrable industrial engineering and experienced skilled people out there to call upon.

Right now, we are watching the manufacturers competing to make graphene faster than one other. More manufacturers are coming into the open with previously secret projects for making graphene. We can expect to see more. They will increase the speeds and improve the product quality.

Graphene manufacturing is already a reality. The continuous manufacture of tether quality graphene material is still some years into the future. However, making single crystal sheet graphene at scale is not impossible. It is just a series of engineering problems to be solved.

References:

[1] X. Xu et al. (2017) Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil, Science Bulletin 62. 1074-1080

[2] Kidambi, P., et al., 2018. A Scalable Route to Nanoporous Large-Area Atomically Thin Graphene Membranes by Roll-to-Roll Chemical Vapor Deposition and Polymer Support Casting. ACS Applied Materials & Interfaces, 10(12), pp.10369-10378.

[3] Ryu, J., et al., 2014. Fast Synthesis of High-Performance Graphene Films by Hydrogen-Free Rapid Thermal Chemical Vapor Deposition. ACS Nano, 8(1), pp.950-956.

[4] Kim, Y., LG Electronics, 2020. CVD and Monolayer Graphene Production and Applications [video] Available at: https://www.youtube.com/watch?v=Oljnh_IJRiI, ( 2:23 to 14:55), [Accessed 21 July 2021].

[5] Graphene-info.com. 2021. CHARMGRAPHENE | Graphene-Info. [online] Available at: <https://www.graphene-info.com/charmgraphene> [Accessed 21 July 2021].

[6] Valmet.com. 2021. The world’s best paper machine: UWF speed record of 1,808 m/min. [online] Available at: <https://www.valmet.com/media/articles/all-articles/the-worlds-best-paper-machine-uwf-speed-record-of-1808-mmin/> [Accessed 21 July 2021].

History Corner

by David Raitt, PhD

ISEC Chief Historian

Space Elevator Fun and Games: Part 3, Japan

The Japan Space Elevator Association (JSEA) was formed after a number of its founding board members had participated in the NASA-Spaceward Power Beaming Space Elevator Challenge in Salt Lake City in October 2007. JSEA activities centered around an annual conference with an accompanying art competition and the Japan Space Elevator Technology and Engineering Competition. The main purpose of the latter is to increase concept development, design and construction and to understand more about tether climber designs as well as power issues with a view to attain an altitude of 30km in the next few years. The Challenges are also in line with the intention of the Obayashi Corporation to have an operational space elevator by 2050.

JSEA has been holding climber and tether competitions since 2009, each with an increasing level of difficulty, but the climbers in these two competitions are electric battery-powered. The purpose of the Space Elevator Challenge in Japan is to provide an actual chance for researchers, engineers and young people to study and enhance their understanding of space elevator related systems. Such a Challenge also offers good chances to spread the basic concepts of the space elevator to a larger audience. Whereas the Spaceward Foundation used a crane in 2007 and a helicopter in 2009 to hang the tether, JSEA used helium balloons due to the lower cost and other potential uses of such an aramid fibre tether hung from the balloons. For the 2012 Challenge, JSEA changed the concept from one of competition to one of understanding the evaluation of climbers and how they should develop as well as the tether. The tethered balloon systems provide the platform to evaluate not only different materials for the tethers themselves, but also differing climber technologies as well as providing basic knowledge about the function of a real space elevator tether.

The Japanese Tether Climber competitions have two types, JSETEC/SPEC and LASER. The first-named competitions feature balloons outdoors and battery-powered climbers. There is also a practical aspect behind the competitions - the plan to scale-up and build a 30km-high tethered balloon system with multi-powered durable climbers by 2020. One of the purposes was to increase not only the knowledge and issues of tether climber designs, but also the investigation of batteries and power issues.

In 2010, the JSETEC competition held on the slopes of Mount Fuji set the challenge for climbers at 300m. There were fifteen teams competing and the winner was Kanagawa University. At the same venue in 2011, there were sixteen entries but no clear winner. At the same place in 2012, the challenge was to reach 1200m, but out of the sixteen climbers using either rope or belt tethers, no team was successful in reaching the height. In the JSEA Space Elevator Challenge (SPEC) competition in 2013 the altitude of 1200m was reached and speeds exceeded 100kph. In the SPEC competition held in 2014 in Fujinomiya City, Shizuoka Prefecture as in 2013, performance measurements relating to speed, weight, efficiency, altitude reached, control capability, etc. were made of elevators that continuously raised and lowered ropes/belts held aloft from balloons moored at altitudes of 200 to 1,200 m to the ground. The overall objectives were the promotion of space elevator related technology and spinout development research plus the dissemination of correct knowledge about space elevators through media. Although there were 19 teams, including from overseas, it appears there were no winners, despite Okusawa climbing two round trips to 1200m and Kanagawa University climbing 123m on the 200m rope with a 100kg payload.

The space elevator technology demonstration event "SPEC 2015 7th Space Elevator Challenge" was announced for August 2015 in Iwaki City, Fukushima Prefecture with some 20 teams from Japan and overseas expected to participate. The organizers aimed to mature the climber technology required for a 1000m climb, and share high altitude climber technology with more teams. The challenge was to have consisted of a joint experiment using a climber model of a space elevator and a tethered balloon coupled with performance measurements of an elevator that continuously raised and lowered a rope/belt connected from a balloon moored in the sky to the ground. But it seems that this year's event may have been postponed. Thus using the climber model of the space elevator and the tethered balloon in 2016 as well, the venue moved to Mito City, Ibaraki Prefecture. The altitude of the mooring balloon was to be a minimum of 100m with a maximum of 400m assumed according to weather conditions.

The Space Elevator Challenge for December 2017 was again announced for Mito City as essentially a competition to compete for the performance of self-sustaining elevators developed for space elevators; mooring of tethered balloons with multiple mooring lines and various competitions using them; and the evaluation of tether lifting performance by self-propelled elevators. Eligible participants included: educational institutions such as universities, high schools, colleges of technology, general companies, individual teams, etc.

It was announced that SPEC would be held again in October 2018 with the organizers also considering the possibility of holding a trial of a competition (GSPEC) that combines climbing up and down with a high-performance robot. However, this event was also postponed, the reason being that since the tournament was set earlier than usual, there was not enough time for the participants to create climbers, and there were not as many participants as necessary for the event. JSEA announced that it would not hold a SPEC event in 2019 due to various factors, but they would hold a climber lift event in January 2019, jointly with Kanagawa University, as an opportunity to evaluate it for the teams making SPEC-class climbers and SPIDER-class climbers. The competition would focus on lifting and deploying the 200m class tethered balloon system and climbing and lowering the climber on the hanging tether. If wind and other conditions permit, hoisting up to an altitude of 400m would also be carried out. In any event, it appears that both this event and the SPEC 2020 event were postponed, the latter because of coronavirus. (http://www.jsea.jp/technology/challenge/).

—————

In an effort to introduce more technologies and thinking, early in 2019, the Japan Space Elevator Association announced that it would organize that summer in Fukushima the competition event SPECxROC - a combination of climber lifting and robot activity. The rules noted that a robot will be lifted by a climber to the designated altitude, will descend to the ground from the height and do designated actions on the ground. The Space Elevator Climber x Robotics Challenge would not only raise and lower the climber itself, but also see the challenge of loading cargo as a step in a mass transportation system. The payload was to be the robot as added value, instead of a simple load such as sandbags. In this challenge, participants were to not only lift an 8kg robot, but also had to consider elements such as the centroid, radio interference to the remote control of the loading device, and so on. There were several reasons for adopting a robot and these were expanded upon for contestants and show the thinking behind the challenges. (http://www.jsea.jp/technology/specxroc/000514.html). The 2019 event handed out several awards in the climber category: for the climber which recorded the highest climbing speed; the payload award; climber with the maximum cumulative altitude in a single window without battery replacement; stable transportation award, and so on. Several of these were won by Kusep-Kana. In the robot category the best robot award was not given, nor was the speed award since no robot was able to reach the goals of both the ground task and the descent task; the payload award for transporting 400g was however awarded. Two SPECxROC challenges were foreseen for 2020 - one in Fukushima in August and one at Niigata Institute of Technology in September. However, with the corona virus pandemic these were postponed. (http://www.jsea.jp/technology/specxroc/).

—————

The Space Elevator Games and Challenges in America, Europe, Japan and elsewhere must be seen as an important step in the process of interesting young people and the general public, as well as scientists and engineers in the concept, design and development of the space elevator. The competitions provided (and still do) incentive for considering and understanding the problems and the technologies, materials and power sources required to bring a space elevator into reality. As noted above, Japan has introduced a new element into space elevator challenges by the addition of robots used not only for climbing. And in Europe, WARR, as well as space elevators and satellites, also focuses on the development, testing and launch of experimental sounding rockets. With ISEC’s new Dual Space Access Architecture, then Space Elevator Games, whether in the USA, Europe or Japan, might seem to be ripe for an even more challenging and fun time by combining a competition for designing, developing, building and launching a small model rocket in conjunction with the present competitions for space elevator tether and climber elements!

Upcoming Events

Members Only Webinar

Sponsored by the International Space Elevator Consortium

Topics: Economic Impact of Space Elevators; Interplanetary Launches; Tether Stresses/Atmosphere Problems; Global Space Train; Tether/Climber interface Study; and Dual Space Architecture

Saturday, August 14th

72nd International Astronautical Congress

Sponsored by the International Astronautical Federation (IAF)

http://www.iafastro.org/events/iac/iac-2021/

Monday, October 25th through Friday, October 29th, 2021

Dubai World Trade Center

Dubai, UAE

Space Elevator Conference

Sponsored by the International Space Elevator Consortium

Topics: Tether/Climber interface & Environmental Benefits of Space Elevators

Coming in Spring of 2022

Location: TBD

73rd International Astronautical Congress

Sponsored by the International Astronautical Federation (IAF)

https://www.iafastro.org/events/iac/iac-2022/

Sunday, September 18th through Thursday, September 22nd, 2022

Paris, France

Contact Us:

You can find us on Facebook, Twitter, Flickr, LinkedIn, Instagram, and YouTube.

Our website is www.isec.org.

Support us:

Sign up to be a member at: https://www.isec.org/membership

You could volunteer to assist with any number of activities...let us know where you would like to help!

You can also give directly using the “Donate” link at the bottom of our website page.

Our unique charity link for Amazon Smile is https://smile.amazon.com/ch/80-0302896.

Does your place of employment do matching funds for donations or volunteer time through Benevity? If so, you can make ISEC your recipient. Our 501c3 number is 80-0302896.